top of page

LSS - Light Steel Structure

Light Steel Structure (LSS) is a construction system made from cold-formed galvanized steel profiles. It provides a lightweight yet strong framework suitable for residential, commercial, and industrial buildings. The steel components are manufactured with high precision and assembled quickly on-site, offering a modern alternative to traditional construction methods.

The thickness of light steel elements typically ranges from 0.8 mm to 4 mm, depending on the structural requirements — with thinner sections used for internal frames and thicker profiles for load-bearing walls and beams.

Why

Fast & Efficient Construction

Light steel systems are pre-engineered and easy to assemble, reducing labor time and speeding up the overall construction process. This results in faster project delivery.

Cost-Effective Solution

Using light steel helps lower overall construction costs due to reduced labor, shorter build times, and minimal waste. It’s an economical alternative to traditional materials without compromising quality.

Environmentally Friendly

Light steel is recyclable and produces less on-site waste, making it a sustainable choice. Its precision manufacturing also reduces material overuse, aligning with green building practices.

How

Design & Structural Engineering

Once we receive a new project, our design team gets to work using advanced tools and other structural design software. We begin by modeling the building’s framework, creating a detailed mesh, and studying the structure from all angles to understand its specific needs.

With our experience, we select the most suitable construction method based on the project’s scale, use, and environmental conditions. During this phase, we carry out several critical analyses, including:

Stress and load analysis

Wind resistance analysis

Thermal expansion behavior

Seismic (earthquake) analysis

Deflection and structural stability checks

This stage ensures that the building will perform reliably under real-world conditions, forming the foundation for a safe, efficient, and long-lasting structure.

Manufacturing

After completing the design and analysis phase, we begin the manufacturing process. Some of the components are produced in our own factory using specialized tools and equipment designed for light steel structure systems. This ensures high accuracy and quality control for the most critical parts.

For other elements, especially those that require specialized manufacturing techniques or equipment, we collaborate with trusted production partners. These partners are carefully selected and work closely with our team to follow exact project specifications and standards.

Whether produced in-house or through our partners, we never compromise on design integrity or material quality. Every component is fabricated to meet the demands of the project, ensuring strength, durability, and a flawless final structure.

Assembly & On-Site Installation

After the manufacturing phase is complete, we move to on-site assembly and installation. This stage is handled by our highly trained and experienced technical team, specialized in working with light steel frameworks of all scales. Over the years, we’ve built a strong, capable crew that understands the full cycle — from design to execution — ensuring smooth and accurate installation.

Our expertise comes from years of hands-on experience in projects ranging from small residential units to large-scale developments. We’ve proudly contributed to several major projects in Egypt and abroad, including residential compounds in Sakarya, Turkey, and served as consultants on landmark developments in Saudi Arabia. These diverse experiences have shaped our methods and improved our ability to solve challenges on-site with speed and precision.

Cladding System

We use Marmox panels from our partner CMB for exterior cladding, providing excellent thermal insulation, waterproofing, and fire resistance. The panels have a core of extruded polystyrene (XPS) foam, coated on both sides with polymer-cement plaster and reinforced with fiberglass mesh for added strength and durability. We’ve also developed custom fixing systems that connect the panels tightly to the light steel frame, creating a solid, weatherproof, and fire-resistant structure.

Light Steel Columns & Beams System

illustrates the use of galvanized light steel profiles in a structural system designed for single-story applications. The columns and beams are formed from cold-rolled steel sheets with thicknesses ranging from 0.8 mm to 1.6 mm. This lightweight framework provides efficient load distribution for walls and roofing, making it ideal for quick and cost-effective construction projects that do not require upper floor loads.

Custom Hinges & Connectors

hinges and connectors used in the light steel system. These elements are primarily standard components, but L-shaped, T-shaped, H shaped, and C-shaped connectors are also incorporated based on the specific structural requirements of each project. Each hinge is carefully selected or custom-designed to meet the project’s load distribution and alignment needs.

In addition to structural support, the connection system accounts for thermal expansion and contraction of steel due to seasonal temperature variations. This flexibility helps maintain structural integrity and prevents stress accumulation over time.

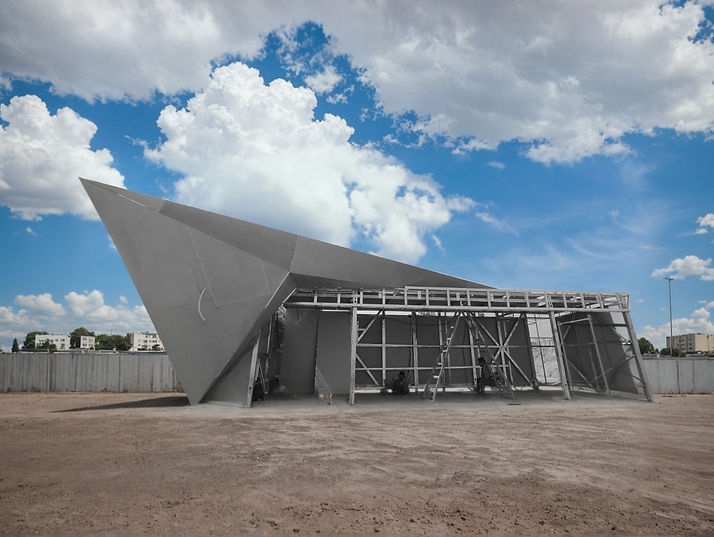

Where

Below are some of the projects where we have implemented LLS (Light Steel Structure) systems — either as the main structural solution or integrated into specific parts of the building such as walls, roofing, or interior framing. These examples highlight the flexibility and speed of LLS construction in a variety of applications.

bottom of page